DLP Technology Today

DLP technology originated from the efforts of Dr. Larry Hornbeck of Texas Instruments in 1987. It was initially developed for projectors and large-screen displays, but it quickly found a niche in cinema projection also because of its high-quality output and reliability. At the heart of this technology is the Digital Micromirror Device (DMD) chip, a remarkable feat of micro-electro-mechanical system (MEMS) engineering, which plays a crucial role in image production on DLP projectors.

An in-depth look at the DMD chip

The DMD chip consists of an array of up to millions of tiny mirrors, each measuring less than a fifth of the width of a human hair. Positioned on a hinge and controlled by individual electrostatic pulses, each mirror corresponds to a pixel in the projected image. These mirrors can be moved rapidly — in some cases up to 5,000 times per second — between an "on" position (which directs the light onto the projector's lens) and an "off" position (which directs the light away from the lens), digitally modulating the light at the microscale to produce sharp, high-resolution images.

The DMD chip operates on the principles of MEMS technology, where mechanical components and electronics are integrated into a single silicon chip. This integration enables precise control of the mirrors in real-time, which is essential for maintaining image sharpness, color accuracy, and high frame rate.

Minimized Gap Between Pixels

Those tiny mirrors, each representing a pixel, are placed very close to each other on the semiconductor chip. This design, where the electronics controlling the mirrors are located behind them, allows for an extremely small gap between the pixels, often referred to as the "fill factor."

The high fill factor of DLP projectors results in less visible gaps between pixels, providing a smoother image with better resolution and sharpness compared to LCD and LCOS (SXRD) projectors where the pixel structure can be more apparent, especially in larger screens.

With minimized pixel gaps, DLP projectors produce seamless images that enhance viewer engagement, making them ideal for high-definition content in home cinema installations.

High ANSI Contrast

ANSI contrast is a measure of a projector's ability to maintain contrast (the difference between the brightest white and the darkest black) under practical viewing conditions rather than in ideal when black and white elements coexist on the same picture frame.

DLP projectors are characterized by high ANSI contrast compared with other projection technologies like LCD or LCOS, which is critical for maintaining image depth and detail, especially in ambient light environments.

This high ANSI contrast ratio provides more vivid colors and deeper blacks in real viewing conditions, improving the viewing experience.

Durability

The construction of DLP chips involves robust materials and a design that inherently makes them more durable. The DMD chips used in DLP projectors are sealed and protected from dust and other environmental factors, reducing the risk of damage and degradation over time.

The sealed design not only protects against dust but also reduces the need for regular maintenance, which is a common issue with other projector technologies where filters must be cleaned or replaced regularly.

DLP projectors are known for their longevity, with the ability to maintain image quality and brightness for extended periods, making them a cost-effective solution and the best platform for new projection light technologies like Laser and Led diodes.

Simpler optical engine

The DLP chip simplifies the design of projectors, making them smaller and simpler in construction. Conventional LCD and LCOS projectors require more parts and a larger setup for color and light management because they use a separate panel for each primary color. In contrast, DLP technology combines everything in a single chip that controls how the light is reflected and projected. This not only makes the internal structure of the projector less complicated but also smaller and lighter.

The use of an RGB laser as a light source is a good complement to the capabilities of the DLP chip. Lasers deliver clear, vivid light directly to the chip, which the DLP technology can then convert into the final image on the screen. This method is more direct and wastes less light, making the projector more energy efficient. The result is a projector that isn't only compact but also offers better picture quality — brighter images and richer colors — with greater efficiency. This combination is ideal for any environment that requires reliable, high-quality projection, from portable business projectors to high-end movie theater projection systems.

Introduction to DLP 4K XPR technology

DLP 4K XPR technology uses an innovative pixel-shifting mechanism to achieve an improved resolution approaching 4K. It does this by diagonally shifting the light reflected from the mirrors in the DMD chip at sub-pixel level, effectively doubling the perceived horizontal and vertical resolution of the projected image.

This micro-movement of the reflecting light from the mirrors allows the projector to output a higher pixel-density image without the need to increase the number of mirrors on the DMD chip. This is a clever use of existing technology to meet modern resolution requirements such as 4K or even 8K.

Here is a video of how exactly the XPR module works

https://www.youtube.com/watch?v=oOS7cpvKAhs

All of today's 4K DLP home theater projectors use XPR technology to bring UHD images into our living rooms.

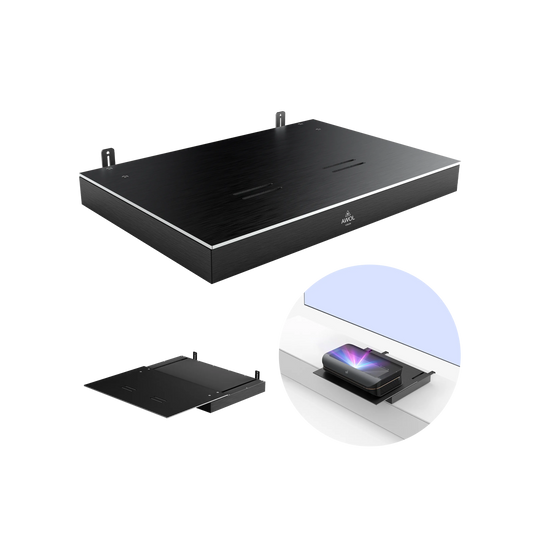

DLP technology in today’s UST laser projectors

Today's Ultra Short Throw laser projectors with DLP chip technology represent a breakthrough in projection capabilities, combining a compact form factor with outstanding performance. UST laser projectors can project large images from very short distances, making them perfect for home and professional environments where the size of the space is no longer a crucial factor.

By integrating DLP technology, these projectors achieve sharper images and more vivid colors, which significantly improves the viewing experience.

The latest RGB laser DLP optical engines allow for a wide color gamut and deep blacks, so images are not only bright but also have high contrast and clarity. In addition, RGB laser light sources are known for their longevity and consistent brightness, which minimizes maintenance requirements and lowers the total cost of ownership.

This makes UST laser projectors with DLP technology extremely attractive for a range of applications, from impressive home theaters to dynamic business presentations and educational facilities. Their ability to project large, sharp images in tight spaces, combined with the durability and color accuracy of RGB laser and DLP technology, transforms them into a combination that's hard to beat.

DMD chips today

The most known DMD chip that most 4K UST Laser projector brands use for their models is the 0.47’ version, like the DLP471TE.

https://www.ti.com/product/DLP471TE

This version can handle up to 5.500 lumens of brightness and its features are quite impressive

0.47-Inch diagonal micromirror array

4K UHD (3840 × 2160) display resolution

5.4-µm micromirror pitch

±17° micromirror tilt (relative to flat surface)

Bottom illumination

High Speed Serial Interface (HSSI) input data bus

Supports 4K UHD at 60 Hz and full HD at 240 Hz

Laser-phosphor, LED, RGB laser and lamp operation

The latest DMD chip from Texas Instruments that is quite interesting and worth mentioning is the new DLP781TE.

It is a large 0.78’ chip with the capability to handle up to 13.000 Lumens of brightness!

https://www.ti.com/product/DLP781TE

0.78-inch diagonal micromirror array

4K UHD (3840 × 2160) display resolution

9.0µm micromirror pitch

±14.5° micromirror tilt

Corner illumination

Supports high optical power density for high-brightness large venue displays

Up to 40W/cm2 total optical power density

2xLVDS input data bus

Supports 4K UHD up to 60Hz

Laser-phosphor, and RGB laser supported

DLP Technology Today

The DMD is one of the most complex micromachines ever built, with million of moving parts that function flawlessly over trillions of cycles. For example, each micromirror in a projector operating for 100,000 hours goes through approximately 2.5 trillion (1012) cycles. If the DMD has 1 million micromirrors, then the total number of cycles for all mirrors is 2.5 quintillion (1018) cycles.

DLP technology, particularly through the capabilities of the latest RGB UST laser projectors, will continue its legacy of the best image quality in the projection industry. With continued advances in technology and a strong focus on sustainability and efficiency, DLP technology will continue to set the standards for what projectors can offer us today and tomorrow.

AWOL Vision

Be the First to Know

Subscribe for special deals, news, and important product information, and get your exclusive $50 discount.